Everything about product labelling

What is labelling?

A label is designed to give more information about the products to which it is applied. The main purpose of a label is therefore to inform people. It is, as a kind of ‘name tag’ for a product. The application of the label is called labelling.

How do you design a label?

After purchasing a blank label, it is of course the intention that the producer can fill it in himself. This is done by using label software.

Label software

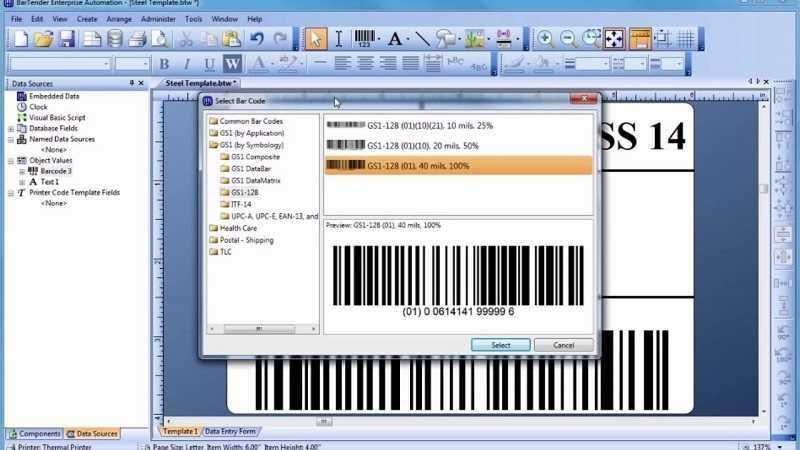

A label software or label design programme is, as the name implies, a programme with which producers can design their own label. Depending on the label software chosen, the programme must first be installed or is immediately available in the Cloud.

To make the process as pleasant as possible, label software has a very user-friendly interface. The programme allows you to add your own texts and images, move them around and generate barcodes. Don’t let this scare you off as a producer, often the programs themselves offer templates to get you started. Each of your own designs can also be saved as a template for later reuse.

Some label software goes beyond designing. With the more comprehensive programmes, the labels can not only be created but also printed. By communicating with the database, the software can ensure that the printers provide a label with the correct information for each product in real time.

Of course, the labels can also be printed in advance using a label printer.

Pre-printed

Besides blank labels, there is also the option of having labels pre-printed. For pre-printed labels, specialists are called in. They are then always looking for the fitting label. They always look for the most suitable base material, the best type of glue and the appropriate finish, for any sector.

What should be on a label?

A label plays an important role in communicating with the consumer. As mentioned earlier, the main purpose of a label is to inform people. However, it can also be used for other purposes. Just think of branding or decorating products, but also shipping addresses, stock management and so much more.

Labels per industry

What needs to be on a label is determined by legislation. The rules concern content, size, colour and so on. They also depend on the label and its industry.

A few examples per industry are:

- Food: Eco-score, food label (Expiration date(THT/TGT), batch code, lot code, ingredients, nutritional values,…)

- E-commerce: LPN code

- Chemicals: UFI code

- Horticulture: Plant passport

- Applicable in every sector: Promo labels

What is a labelling machine?

A product can be labelled either manually or mechanically. Manual labelling is often chosen when only small quantities need to be labelled. Applying the labels yourself saves the cost of a labelling machine. In exchange, however, you are left with a time-consuming task, which is even more difficult with unique product shapes. In addition, manual labelling is less accurate and there is always a labour cost for the employee applying the labels.

For large quantities and high speeds, a machine solution is often offered. A labelling machine is specially designed to apply or print and apply labels automatically. And that on almost any material: glass or plastic bottles, cardboard boxes, foil packaging, etc.

Depending on the production capacity, one can choose between semi- or fully automatic labelling systems.

Types of labelling machines

There are 3 different types of labelling machines: apply, print & apply and pallet labellers.

Labelling line

Normally a labelling machine is connected to an existing production line. However, this is not always efficient or even possible. Sometimes a new line has to be created. That is why there are labelling lines. A labelling line consists of a labelling machine and its own conveyor belt, which simplifies implementation.

Labelling variable heights

With the right labelling machine, products of different heights can be labelled in the same production line. The machine has a sensor for this that measures the height of each product. Once the machine has calculated the height, it automatically adjusts its applicator to the correct position.

Labelling boxes of different heights at DassyApplicator

Every labelling machine has an applicator. An applicator is the part of the machine that applies the labels to the products. It is impossible for an applicator to stick every kind of label on every kind of product. In order to always deliver quality work, there are many different types of applicators. It is therefore important to know which applicator fits best in the production line.

Of course, it is not expected that every producer knows immediately which applicator he needs. For that, they can always call on an expert. Based on a few questions, they know the best solution.

A few of these questions can be:

- Which kind of surface does the product have?

- What material is the product made of?

- What is the speed of the production line?

- On which position should the label be placed?

Position of the label

When it comes to the position of the label, almost anything is possible. Whatever you want, it is possible. There are in fact many types of labelling:

- Side labelling: The label is stuck on the side of the product. This can be done on 1 or 2 sides.

- Corner wrap labelling: A single label is attached to two sides. The label is stuck over the corner.

- Front & back labelling: The label is placed on the front and/or the back.

- C-labelling: A single label is applied to the top, bottom and side. This type of labelling is often used in the food sector.

- U-labelling: U-labelling is the same as C-labelling, except that here a single label is applied to both sides and the top of the product.

- Wrap-around labelling: The label is wrapped around the product. This technique is also called wrap-around labelling. It is often used with bottles, large or small.

- Top & bottom labelling: A label is applied to both the top and the bottom of the product.

- Seal labelling: The label is placed over the closed opening of the product.

Would you like more information about the different label positions? Learn more about the different labelling methods with accompanying example videos.

Which brands does Codipack Group distribute?

ALtech

Since 1969, ALtech has been providing clear identification of products. During all these years, ALtech has grown along with the sector and its needs. So that now, in our current society, where identification is almost an indispensable part of every manufacturing process, they can also offer the right solution. Thanks to the accumulated knowledge and experience, they offer high-quality labelling machines for every identification purpose.

Evolabel

Evolabel was founded in Sweden in 2007 under the name Autolabel, because the employees were convinced that there could be fun in printing and labelling. Together they looked for a way to make the labelling process as easy and pleasant as possible. They marketed their products with one main idea in mind: ‘Simplicity through technology’. Always striving for innovative, attractive and high-quality labelling solutions.