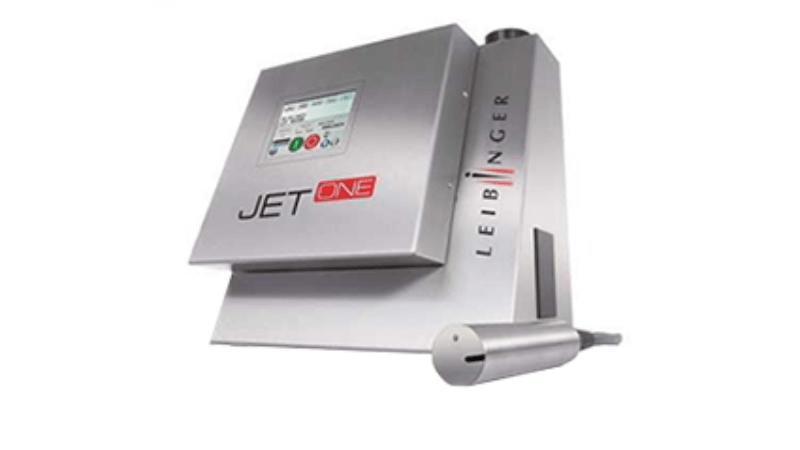

Leibinger – inkjet

When was Leibinger created?

Since Paul Leibinger started the family business with the manufacture of number machines in 1948, the company has continuously improved its development and production. Leibinger is a specialist in precision mechanics and an international company with state-of-the-art technology and the constant values of a family business. For decades, Leibinger has followed a production strategy that focuses on the highest quality. This means that all quality-relevant work steps have always been carried out in-house. And at Leibinger this starts with the manufacture of the smallest parts, such as special screws for the print head.

The problem with continuous inkjet printing is that the ink must dry quickly. So every production interruption often results in dried ink and clogged nozzles.

Not so with Leibinger’s unique Sealtronic technology. When production stops, the nozzle retracts, closing the ink loop and we prevent drying out. To start again, the nozzle slides back out and continues printing – without the need for cleaning or rinsing cycles. After all, why clean something that isn’t clogged?

This is what makes Leibinger unique

Leibinger is active in:

- Food & Beverages

- Chemicals, pharmaceuticals and other consumer goods

- Industrial goods

Plant passport

Due to EU regulations, plant manufacturers must print a “plant passport” on each product. With the botanical name, country of origin and traceability codes, the passport must be clearly printed on the smallest commercial unit, e.g. individual plant pots and containers. Leibinger also has the solution for this.