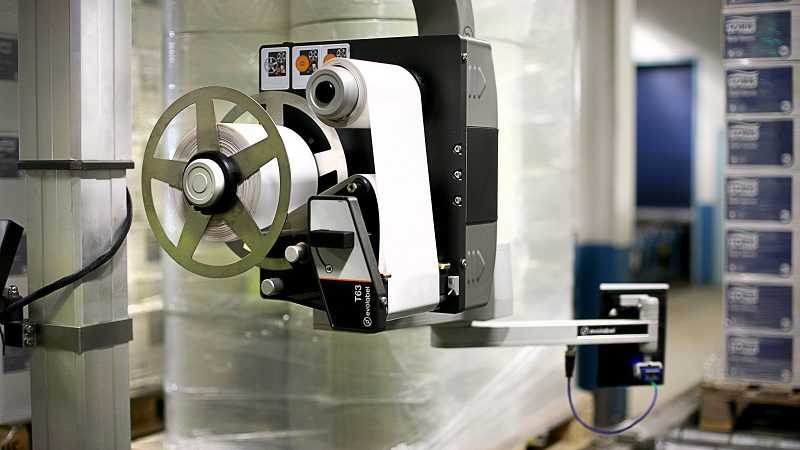

Evolabel FlexWipe Pallet labeling system

-

Labelling 5 pallets per minute, 2-sided

-

Safety - standard CE IIA

-

Landscape application also possible

-

Most compact pallet labeller on the market

Evolabel FlexWipe pallet labeling system turns traditional pallet labelling up-side-down.

Instead of being dangerous, hard to use, large, slow and expensive, the Evolabel FlexWipe system is totally safe, user friendly, compact, fast and cost effective.

Enhancing safety – The unique Tactile arm eliminates any risk of crushing between the moving applicator arm and the printer or the pallet. If you put your hand in the way, the stepper motor driven arm stops and the system gives an alarm. The Tactile arm together with the Pivotable machine mount, negates the need of expensive guarding. This does not only reduce cost and release floor space, it also gives direct and quick access to the system for the operator. The label roll is replaced within 20 seconds and it takes only a minute to replace the print head or print roller when needed.

Front, Side and Rear pallet labeling

The free motion apply (patent pending) allows the same configuration to apply either of the two adjacent sides (side+front or side+back) within 12 seconds. This includes validation of all barcodes on the GS1 SSCC label. The FlexWipe system can label all three sides without having the pallet to stop if check scanning is not required.

Essity Hygiene and Health

At Essity Hygiene and Health in Lilla Edet, Sweden, the Evolabel FlexWipe system prints and applies 5 pallets per minute, on two sides including verification of all barcodes. More important still, is the fact that the system is totally safe. Both the risk of pinching between the applicator arm and the printer and the risk of getting stuck between the pallet and the whole system are eliminated with intelligent solutions.