Coding boxes with the Diagraph IJ4000

Hundreds at a time. Bottles, vials and cans of all shapes and colors. Empty when they start their journey, filled and labeled when they go onto the pallets. At Jodima, they make car coolants, windscreen wash, cleaning sprays for rims, dashboards… The challenge for their labeling is therefore flexibility. An interview with production coordinator André De Nijs.

“We do everything here ourselves,” André begins. “We mix, fill, label and put everything ready on the pallets. And all that as automatically as possible. Does an order come in via our ERP system? Then it automatically notifies our suppliers. So that, for example, our one-liter bottles arrive just in time. Without us having to make any calls.”

All-rounder

“Almost no product has a separate line here. The surface area of our hall doesn’t allow for that. Each line must therefore be able to handle multiple products. That calls for a flexible production process in which every component can go along. From the filling installation to the labeling solution. For example, we have a labeling system that not only labels all around, but also one and two sides. Without loss of quality. Because all products that leave here eventually end up on a store shelf. The visual aspect is important in our industry. If the label is crooked or uneven, we sell less. It’s that simple. If it doesn’t look good, it reflects on the content anyway.”

“To the customer, a properly applied label seems so obvious… but it’s not. I think labeling is one of the more complex topics within our production. There are so many factors involved: temperature, bottle shape, speed, label material, print quality… Everything has to be right.”

“Flexibility to me also means quick changeovers. That determines our output, turnover and service to our customers. We have to be able to switch quickly between all those products. Both digitally and with manual operations. If our operator spends more than an hour converting our labeling machines, I don’t need to do it anymore. That too must be able to be done quickly.”

More quality, fewer problems

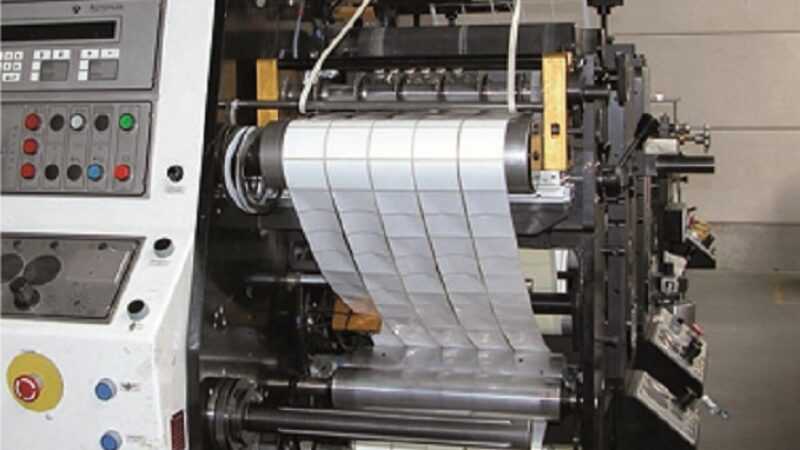

“Our latest collaboration with Codipack is the Diagraph. An inkjet printer that is responsible for applying barcodes to cardboard boxes. That inkjet prints directly on the boxes and works in tandem with a labeling machine. It is one of the few lines that constantly runs the same product.

“The Diagraph’s travelling arm guarantees the right printing distance every time. Because a cardboard box is not dimensionally stable. By allowing the print head to move with it, the quality remains high. And that is important for something as precise as a barcode. Not every printing system can handle this quality at this speed. Another advantage is that the co-movement wheel avoids the boxes bumping into the device.”

“We have been printing with this Diagraph for two years now. And I haven’t had any problems with it – not even a clogged nozzle. The line has never stopped, not even for maintenance. It cleans itself in a fraction of a second. And even if a box passes just then, there is no loss of quality.”