Understanding lifespan printhead

The printhead is a very sensitive but important part of every label printer. All printer components must be treated with the necessary care. This is especially true for the printhead. Here you can read what to do to make this critical component last as long as possible.

Certain printer parts need to be replaced over time. Usually these are consumables, such as labels or the ribbon. Also, certain wear parts, such as print heads and platen rollers, are consumables that need to be replaced periodically.

The print head is in constant contact with moving parts, such as labels, ribbon and platen roller (the pressure roller directly under the print head). Not only the quality of the labels and the print ribbon, but also proper maintenance and handling have a direct influence on the service life.

Compare it to the tyres on a car: if you don’t change them regularly and don’t balance and align them properly, you will have to replace them much sooner than someone who has followed the tyre manufacturer’s maintenance recommendations.

1. Printhead cleaning

It is recommended to clean the print head and platen roller each time you change the print ribbon for thermal transfer printers or after each media change for direct thermal printing. Use the appropriate cleaning agents or a non-abrasive and lint-free cleaning cloth soaked in isopropyl alcohol (90% or more). This is the easiest way to make the printhead last as long as possible.

Check the degree of soiling on the cleaning wipe to determine if more frequent cleaning of the print head is necessary. Certain materials and environmental conditions can encourage the accumulation of residues. In this case, you must clean the print head more often.

Never touch the print head with your bare hands. Oil or other contaminants on your hands can reduce the life of the print head.

Dust fibres on the media pad or in the printer can be removed with a brush and/or compressed air. Only use approved compressed air holders. Never use compressed air from pneumatic hoses or compressors, as they usually contain water vapours or other distillates that can cause problems with the life and operation of these parts. Take care never to aim the compressed air jet directly at the print head: its thermal properties may damage the protective layer on the print head components.

2. Choosing the right media

As mentioned, the print head is subject to wear and tear and will eventually reach the end of its service life. However, the question is when.

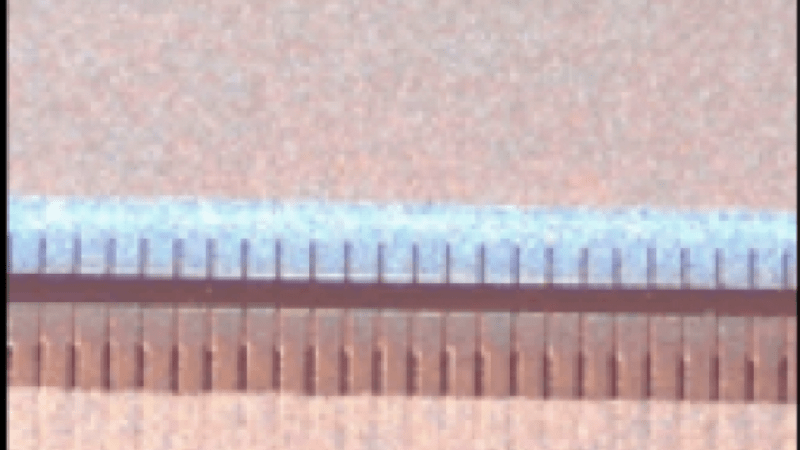

If you do not clean the printhead, unwanted residues will accumulate. The printer will still print, but you have to keep increasing the heat to get the same print quality. As the heat is increased and more residue builds up, more residual heat is left in the printhead. This eventually causes the protective layer to crack, damaging the printhead.

The amount and rate of residue build-up depends not only on the type of labels, print ribbon and environmental conditions, but also on printer maintenance and cleaning frequency.

A constant friction is exerted between the print head, the print ribbon and/or the labels. This eventually wears away the protective layer of the printhead. Once the protective layer is gone, the electronic elements are unprotected and can be damaged. For each printing method, it is important to choose a good quality product.

With direct thermal printing, the labels are in constant contact with the printhead. Therefore you should also pay special attention to the quality of the labels for this printing method. The printhead can fail prematurely if the substrate is of poor quality, if there is excessive glue penetration or if the perforation is made on the front of the print material.

When using the thermal transfer method, care should be taken to ensure that the print ribbon and labels are of good quality and are aligned with each other. The back of the print ribbon is in constant contact with the print head. Using poor quality material or being exposed to an environment that does not comply with the printer’s specifications can cause unwanted residue to build up on the print head.

We always recommend using a ribbon that is slightly larger than the label, so the label does not come into contact with the print head. Good quality ribbons protect the printhead from the abrasiveness of the label material.

The ribbon can also cause electrostatic discharge (ESD), which can damage the printhead parts beyond repair. Always use original spare parts.

3. Printer Maintenance

You can prolong the life of the printhead by cleaning the printer and the printhead regularly. Proper maintenance and precise adjustment are also important.

Use only original parts to keep your printer working properly.

4. Environmental conditions

Environmental conditions can have an adverse effect on the printer and labels.

Non-compliance with the printer specifications may result in a shorter printhead life. If the printer is likely to be exposed to water and extremely high or low temperatures, it may be advisable to place the printer in a protective casing.

If you do not observe the prescribed storage conditions, labels and print ribbons can be damaged. This can unintentionally change the properties of the labels and print ribbons, causing the print head to not react as expected and/or the accumulation of unwanted residues. All this is easily prevented by proper storage of labels and ribbons.

Do you want more information about our labels and ribbons? Do you want a quotation for print heads? Would you like to call on our technical service for maintenance or repair of your label printer? Do not hesitate to contact us. We will gladly help you.