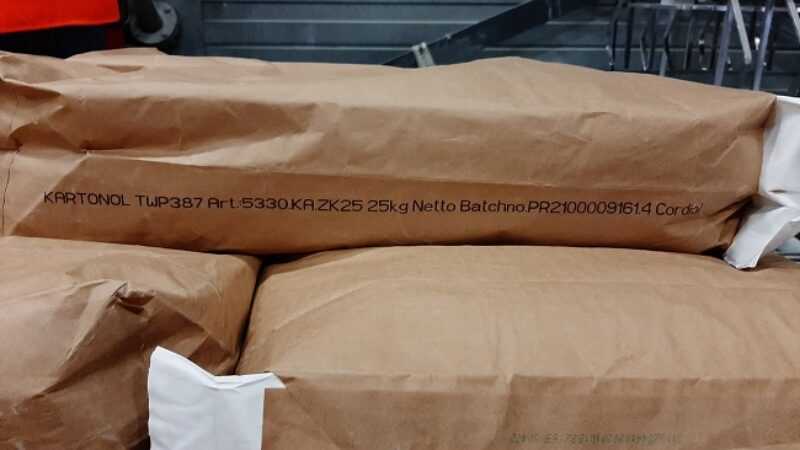

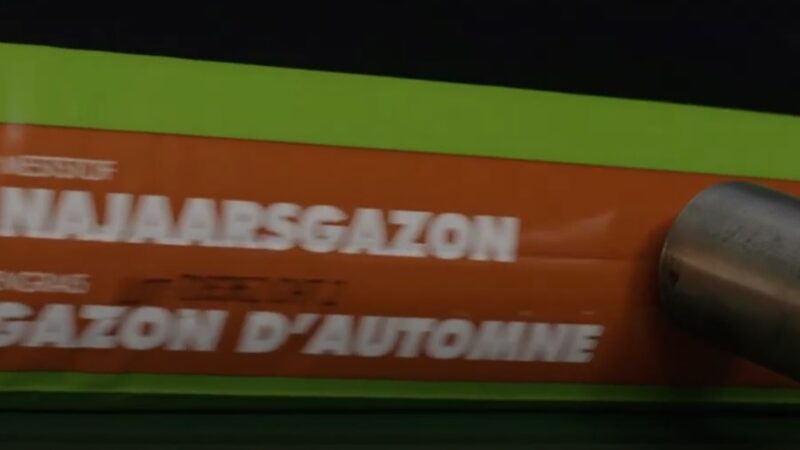

Industrial printing on packaging bags

Inkjet printer for packaging bags

Bag marking must be fast and reliable without compromising on the print quality of the marking. This is because bag marking of bulk materials often takes place under rough and harsh environmental conditions. High dust pollution, temperature fluctuations or vibrations are the rule rather than the exception. High-contrast and well legible print results can be easily achieved here despite the difficult environmental conditions. In many industries, it is even required by regulations, customers or retail chains to apply high-resolution prints such as 1D and 2D codes.

Bulk materials include the following branches and products

- Building materials industry

Sand, gravel, lime, cement, gypsum, concrete mix, crushed stone, grit, powder coatings, ceramic powders, granules - Food industry

Flour, cereals, sugar, salt, starch, coffee, food additives, seeds, rice, baking raw materials, food powder, tea, spices, malt - Paper industry

Starch - Chemical industry

Pigments, fillers, granules, fertilizers, chemicals, starch, sulfur, sodium, calcium, talc, powder, plastic powder - Feed industry

Pellets, mineral feed, pet food

How to mark bags of bulk materials?

In the majority of cases, marking is done after the product has been filled into the bags or pouches. In this case, the filled bags move on conveyor belts and the marking is applied directly to the bags from above or from the side. The challenge with bag marking from the side is to ensure an even print area and the correct distance between the product and the print head. This is achieved by correctly guiding the filled bags using guide rails.

If, on the other hand, marking takes place before the bags and pouches are filled, dust pollution generally plays a subordinate role. This also allows high resolution printing results to be achieved. Information such as barcodes or data matrix codes can then simply be printed directly onto the bags. Printing then usually takes place from above.

Information has to be applied like

- Best-before date

- Production date

- Filling date

- Batch numbers

- Product information

- Layer codes

- 1D codes

- 2D codes

- Weight codes

- UFI Code

- Unique Device Identification (UDI) data

Suitable coding and marking systems for bulk materials

Fast, sturdy, reliable

Under which conditions the marking must take place, whether the marking takes place before filling or afterwards and which printing result is to be achieved, these are the requirements to be specified for a coding and marking system. Codipack Group has several suitable coding and marking systems which have proven to work very well for bag marking.